中国の金属保護フィルムメーカー

As a specialized manufacturer of metal protection films, we understand that the challenges and needs of each customer are different. This is where we come in: we are able to work closely with our customers to carefully select and customize the protection solution that best suits their specific needs. We are experts in metal finishing, providing films that are extremely clear, tougher and more abrasion-resistant, reducing the need to rely on different adhesives for different materials.

We are committed to utilizing our expertise and industry experience to provide you with solutions designed to improve your company's profitability and productivity, ensuring that your metal assets are optimally protected in any environment.

Combined Protection Solutions for Aluminum Surfaces

Aluminum is renowned for its lightweight, strength, and resistance to corrosion, making it a preferred material across a wide range of industries including aerospace, automotive, construction, and electronics. Its ability to be formed into sheets or extruded into profiles enhances its versatility for various applications, from structural components to intricate design elements.

Despite its robust nature, aluminum surfaces are prone to damage during fabrication, handling, storage, and transportation. Scratches, dents, and contamination can compromise the material’s integrity and aesthetic appeal, leading to potential product failure and increased costs due to rework or replacements.

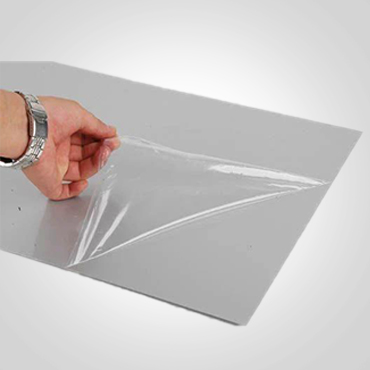

Essential Protection for Aluminum Sheets and Profiles

To safeguard the quality and finish of aluminum during critical phases of its lifecycle, protective films are employed extensively. These films are specially designed to:

Prevent Damage

Protective films shield aluminum sheets and profiles from mechanical damage such as scratches or abrasions, as well as from dirt, debris, and fingerprints that can occur during manufacturing processes.

Preserve Aesthetics

For industries where visual appearance is crucial, such as in architectural applications or consumer electronics, maintaining the pristine condition of aluminum surfaces until the point of installation or sale is vital. Protective films ensure that these surfaces remain untouched.

Facilitate Processing

Films also assist in the easier handling of aluminum materials during machining and assembly processes, preventing direct contact and reducing the chance of surface damage.

カスタマイズ可能なソリューション

Depending on the specific requirements of the aluminum applications, aluminum sheet and profile protective films can be tailored in terms of thickness, adhesion properties, and UV resistance to meet the demands of both indoor and outdoor environments.

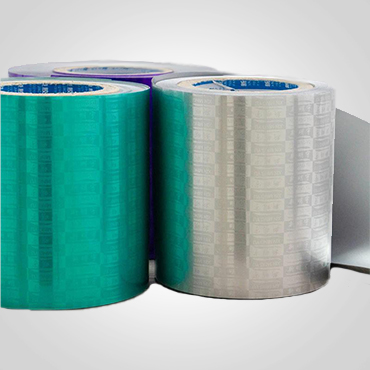

Aluminized PET Films Beyond Aluminum Sheets and Profiles

Aluminized PET films are made using a vacuum aluminizing process in which molten metallic aluminum is evaporated under high vacuum conditions and then aluminum atoms are deposited on the PET film in a vacuum evaporation chamber to form a composite film with barrier properties.

As a further extension of aluminum protection, aluminized films represent a specialized class of protective films used primarily on highly reflective aluminum surfaces. These films are essential for:

Enhancing Reflective Properties

Aluminized PET films retain the reflective properties of the surface, which is essential for applications such as lighting equipment, solar panels and heat reflectors.

Protection Against Environmental Factors

Like bare aluminized PET films, these films protect against physical and environmental damage. However, they are specifically designed to protect against oxidation, which affects the reflective properties of aluminized surfaces.

Advanced Aluminized PET Film Lamination Process

● Solvent-free and odorless

● Excellent radiant reflective heat resistance

● Good chemical resistance

● Abrasion testing

● Adhesion after wet flex testing

Metal Protection Films Overall

| 特徴 | アルミプロファイル保護フィルム | アルミシート保護フィルム | Aluminized PET Film |

| Material Properties | Tear-resistant, adaptable to various shapes of aluminum profiles | Scratch resistant, suitable for covering flat or large curved aluminum panels | Coatings may be used to increase reflectivity and UV resistance |

| 申し込み | Protects doors and glass windows from dust, stains and scratches | Protect hard surfaces such as furniture and floors from wear and scratches | Insulation wrapping, sealing and waterproofing, fixed bundling, warning signs |

| Stickiness | Variable adhesion, adjust the adhesion level according to the application scenario | High adhesion, maintains long-term adhesion, strong protection stability | Variable adhesion, adjust the adhesion level according to the application scenario |

| Transparency | Usually translucent or opaque to prevent damage to visible | Usually opaque to minimize direct sunlight and damage | May be transparent or have a decorative reflective coating |

| Installation | Needs to be carefully cut and fitted to the shape of the profile | Relatively easy to fit to large flat surfaces | Requires professional installation to ensure coating effect |

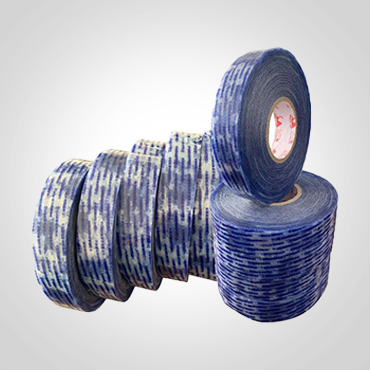

Advanced Protection Film for PVC-Coated Metals

Optimize the durability and appearance of your PVC steel components with our premium plastic protection films. Designed for PVC plastic steel surfaces such as door frames and window sills, our protective films protect against scratches, dirt and abrasion caused by environmental exposure. These protective films are essential in situations where PVC steel elements are exposed during construction, transportation or installation.

Protective Film For Plastic And steel Surfaces

Plastic surface protection films are typically made from multilayer composites such as polyethylene (PE) and polypropylene (PP), which are produced through extrusion, printing and coating processes. The proven performance of protective film products will help ensure your performance and appearance.

- Functional: Only suitable for hard surfaces of plastic steel.

- Upholstery protection: protects windows, doors, cabinets, etc. from paint, dust or other building materials during the decorating process.

- Decorative aids: Protective films can be printed with patterns or colors, which can play a decorative role to a certain extent.

- Cost-effective: The use of protective film is a cost-effective preventive measure compared to replacing or repairing damaged upholstery.

Suitable For Many Metal Surface Applications

Architecture

Used for wall cladding, facades, roofs, interior design, entrances, and other building component protection.

Aluminum Profiles

A wide range of protection solutions for anodized and powder coated aluminum profiles.

Home Improvement

Protect aluminum elements in your home, such as door frames, window frames and aluminum furniture, from scratches and abrasions during the renovation process.

Packaging

Aluminized films can be used for highly protective packaging for food, pharmaceuticals and cosmetics, providing excellent barrier properties to protect products from light, oxygen and moisture.

Yes, many aluminum profile protection films are made with environmentally friendly materials and can be recycled.

High-quality aluminum sheet protection film will not affect the color or gloss of aluminum panels and will not leave marks or adhesive residue after removal.

関連商品