Aluminum Foil Pharmaceutical Composite Film Manufacturer in China

As a leading manufacturer of aluminum foil pharmaceutical composite film in China, we specialize in high-performance films used to protect pharmaceuticals. These composite films meet strict industry standards and are a trusted choice for pharmaceutical companies worldwide. Whether it's over-the-counter or prescription drugs, our films ensure that medicines are protected, safe and long-lasting in harsh environments.

Applications: Blister packs, strip packs and other pharmaceutical applications provide reliable protection for sensitive drugs.

Comparison With Other Packaging Materials

Superior Barrier Properties

Pharmaceutical aluminum composite films have extremely high barrier properties that protect against oxygen, moisture and light, ensuring the long-term stability of pharmaceuticals. In contrast, other materials such as PVC and PE have poor barrier properties and do not offer the same level of protection.

Suitable For High-demand Medicines

The aluminum composite film is usually used for packaging of high-end medicines, especially those that need to be protected from moisture and oxidation. pvc and PE are more commonly used for low-cost packaging or over-the-counter medicines.

Opaque and Protective

The aluminum composite films are opaque and can effectively protect light-sensitive medicines from external factors that can affect their efficacy. Other films such as PET and PVDC coated films are commonly used where translucent packaging is required.

High Temperature and Humidity

Resistance aluminum composite film has better temperature and humidity resistance than other common materials and is suitable for pharmaceutical packaging in high temperature or humid environments.

Post-processing needs

Pharmaceutical aluminum composite films often require post-processing (e.g., cutting, stamping, heat sealing, etc.), and they perform better after processing than other packaging materials, especially in high-end pharmaceutical applications.

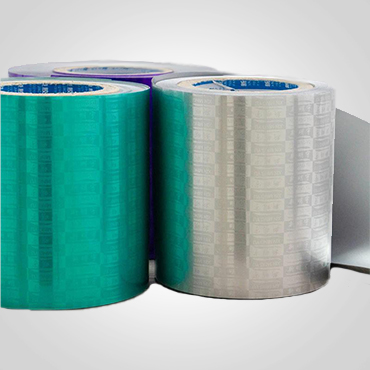

Explore Our Comprehensive Range Of Pharmaceutical Composite Films

We offer a variety of pharmaceutical packaging film solutions to meet your specific needs.

Aluminum Foil Pharmaceutical Composite Film:

Pharmaceutical aluminum foil is mainly processed into the following types of packaging materials:

Blister Packs: Provide individual packaging for tablets and capsules, usually combined with PVC or PVDC layers.

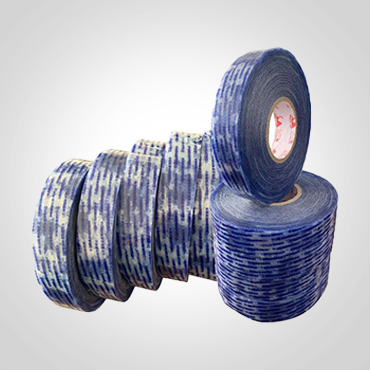

Strip Packs: Provide sealed strip packaging for small doses of drugs, sealed using heat sealing technology.

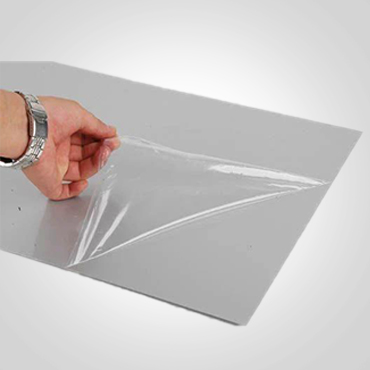

Cold-formed Aluminum Composite Film:

Products processed from cold-formed aluminum foil include:

Cold-formed Blister Packaging: Provides a higher level of protection for sensitive drugs. Its packaging design does not require the addition of a heat seal layer, forming a packaging composed entirely of aluminum to provide optimal air and moisture barrier properties.

If you are interested in the application of cold formed aluminum foils, you can find more detailed information about pharmaceutical composite sheet solutions.

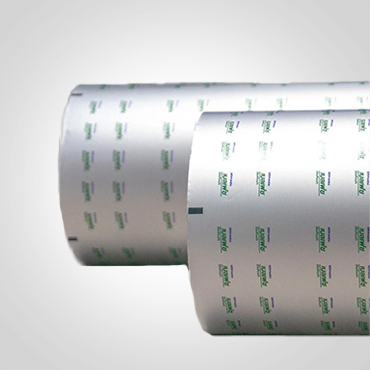

Printable Composite film:

Ideal for customized brands, our printable composite foils offer high protection and excellent printability for pharmaceutical labeling needs.

Different Types of Aluminum Foil Pharmaceutical Composite Film

Multilayer Structure Of Aluminum Foil Pharmaceutical Composite Film

The selection and functional design of each layer of materials have their own unique purpose, aiming to provide better protection, durability and adaptability. Common composite film structures generally include outer layer, middle layer and inner layer, and the materials and functions of each layer are very important.

Outer layer (PET, PA, etc.): Provide strength, wear resistance, mechanical support, and prevent damage to the film surface.

Middle layer (aluminum foil, aluminum layer, etc.): Effectively isolate oxygen, moisture, light, etc., to protect the stability of the internal products.

Inner layer (PE, PVC, etc.): Direct contact with the product, safe, non-toxic and has good chemical stability to ensure the quality of medicines and foods.

This multilayer structure design enables the composite film to provide synergy between layers to meet the specific needs of different product packaging.

Processing Technology of Aluminum Foil Pharmaceutical Composite Film

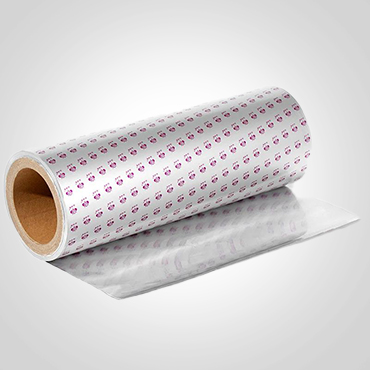

Printing

High-precision printing technology allows images and texts to obtain clear and bright colors. The ink used in the printing process meets safety standards and will not react adversely with drugs.

Gluing

Apply the appropriate adhesive evenly to one or both sides of the aluminum foil by rolling, scraping or spraying.

Slitting

Use a high-precision slitting machine for longitudinal and transverse cutting, and the cutting size can be adjusted to meet various packaging needs. This step requires extremely high dimensional accuracy and edge neatness to ensure that each piece of aluminum foil has good packaging performance.

Outstanding Features of Pharma Composite Films

Tablet Pharmaceutical Packaging

For various tablet medicines such as cold medicine, antipyretic medicine, antibiotics, etc., the tablets are encapsulated one by one in blisters formed by a composite of aluminum foil and plastic hard sheet. The aluminum foil provides good barrier protection to prevent the medicine from getting damp and deteriorating.

Capsule Pharmaceutical Packaging

Various capsule-form drugs, such as vitamin capsules, health care capsules, etc. Aluminum foil can effectively block the influence of external factors on the capsule to ensure the integrity and efficacy of the capsule.

Granule Medicine Packaging

For granule medicine such as cough granule, cold punch, etc., aluminum foil composite pouch packaging can prevent moisture, odor, and maintain the dryness and quality of granule medicine.

Pill Medicine Packaging

For Chinese medicine pills and so on, aluminum foil packaging can prevent pills from sticking, mildew, and prolong its preservation period.

4 Types of Aluminum Foil Pharmaceutical Composite

Film & Ordinary Aluminum Foil Differences

| Features | Pharmaceutical Composite Aluminum Film | Ordinary Aluminum Foil |

| Manufacturing standards | Manufactured in accordance with strict pharmaceutical packaging standards (such as GMP, ISO 15378). | Meets general food safety standards, but does not have the strictness of pharmaceutical grade. |

| Structure and materials | Multi-layer structure, usually including aluminum foil layer and plastic film layer such as polyester (PET) and polyethylene (PE). | Single-layer or no plastic layer structure, mainly used for food packaging and household use. |

| Barrier properties | Provides extremely high barrier properties, almost completely blocking oxygen, water vapor and light. | Provides basic barrier properties, suitable for food packaging but not enough to meet the protection needs of high-end pharmaceuticals. |

| Applications | Designed specifically for pharmaceutical packaging, such as blister packaging and strip packaging, which are in direct contact with drugs and need to meet high hygiene standards. | Widely used for food cooking, storage and household purposes, it is relatively loose compared to pharmaceutical packaging standards. |

How to Choose the Thickness of Aluminum Foil Pharmaceutical Composite Film?

1. 20μm – 25μm

Mainly used for blister packaging of solid drugs such as tablets and capsules. Generally used in combination with PVC, PVDC or PP. Suitable for drugs with high storage environment requirements.

2. 25μm – 30μm

Suitable for small-dose drug strip packaging, such as individually sealed tablets, powders, etc. Can be used to print brand names, instructions for use, etc. to enhance brand recognition. Provides good moisture-proof, light-proof and sealing properties.

3. 45μm – 60μm

Adopts 100% aluminum foil structure (aluminum-nylon-PVC composite) with the strongest barrier properties. Suitable for highly sensitive drugs, such as those susceptible to humidity and oxidation. 60μm aluminum foil is used for special drugs stored in extreme environments.

If your customers require stronger protection, cold-formed aluminum foil of 45μm and above can be recommended, while conventional pharmaceutical blister packaging generally chooses 20μm – 25μm aluminum foil.

Pharmaceutical composite films are commonly used for:

Blister packaging:Blister packaging of tablets and capsules to provide safe and secure protection.

Cold Forming Foils:Used for blister packaging to provide additional protection against degradation of sensitive drugs.

Strip Packaging:Used to package individual doses of medications to provide consumer convenience and safety.

Unit Dose Packaging:Suitable for small and single dose medications for increased portability and ease of use.

Lidding Foils: used as a cover for blister packs with a variety of sealing compositions that adhere to the plastic substrate.