Composite Film Manufacturer in China

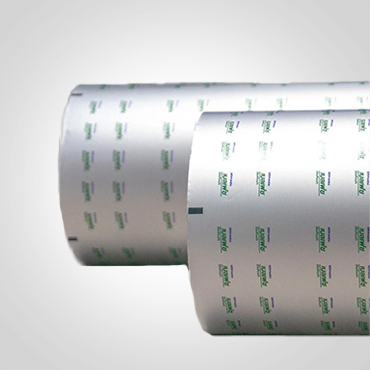

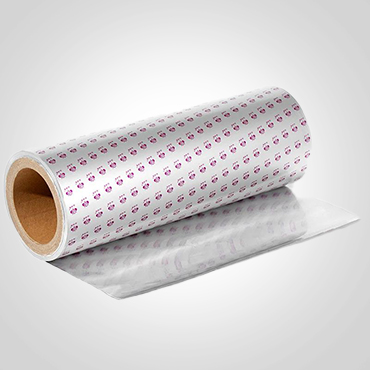

We specialize in manufacturing high-quality protective films for various industries, including pharmaceutical aluminum foil, food-grade films, floor protection films, and metal protection films. Our films are designed to protect sensitive items from external elements such as moisture, dust, and physical damage during production, transportation, and storage.

Our protective films can be customized in various thicknesses, sizes, and configurations to meet specific requirements. Additionally, our products are designed to provide superior barrier properties and durability, ensuring optimal performance and safety.

Detailed Specification

| Material | Aluminum, Plastic, PE, PET, etc. |

| Surface treatment | Laminating, Coating, Printing |

| Barrier Properties | Moisture, Oxygen, UV Protection |

| Application | Pharmaceutical Packaging, Food Packaging, Floor and Surface Protection |

| Customization Options | Thickness, Size, Adhesion, and Color |

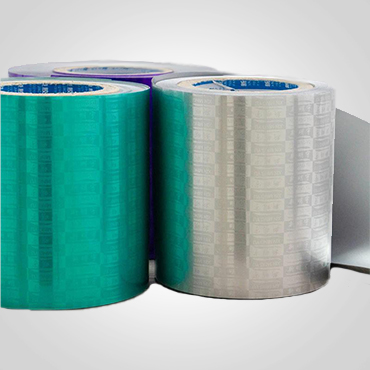

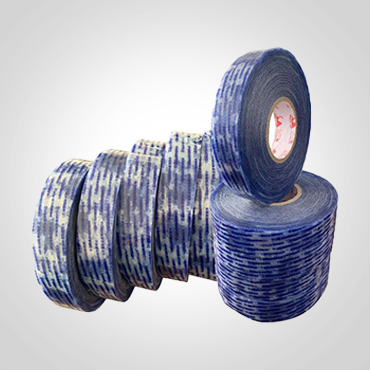

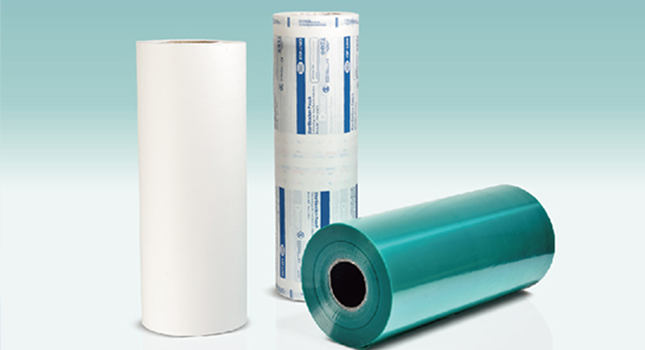

Different Types of Composite Film

Why Choose Our Composite Film?

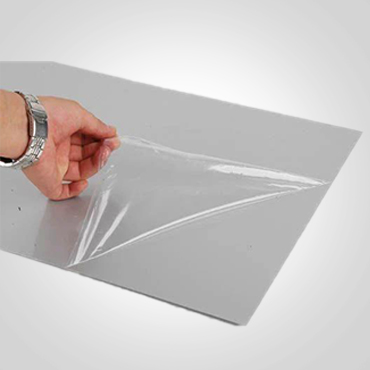

Composite films provide exceptional protection and performance across multiple industries. Our high-quality films offer excellent barrier properties, shielding sensitive products from moisture, oxygen, and UV exposure during storage and transport. With outstanding strength and durability, they protect against physical damage, such as scratches and dents, ensuring your products stay intact. Whether used in pharmaceutical packaging, food packaging, or floor and surface protection, our composite films maintain their integrity under harsh conditions, offering reliable, long-lasting protection for your valuable items.

Wide Applications Of Composite Film

Our laminated aluminum films are used in a wide range of industries to provide reliable protection and durability for sensitive products. In the pharmaceutical industry, they are used for drug packaging to protect against moisture, light and oxygen, ensuring sterility and quality. In the food industry, they keep food fresh and safe during storage and transportation. In the building and flooring industry, they protect surfaces from damage, while in the electronics industry, they protect components from moisture and physical damage. These films are versatile solutions in numerous fields, ensuring optimal protection and performance.Premium Production Process For Composite Films

Reliability and Durability You Can Trust

Our films are designed to meet specific barrier requirements, ensuring optimal performance in moisture, oxygen, and UV resistance.

Highest quality production standards guarantee durability and long-lasting protection. Superior strength prevents scratches, tears and punctures, ensuring your products are always protected. IP55

to IP69.

- Video

What is Composite Film and How is it Used?

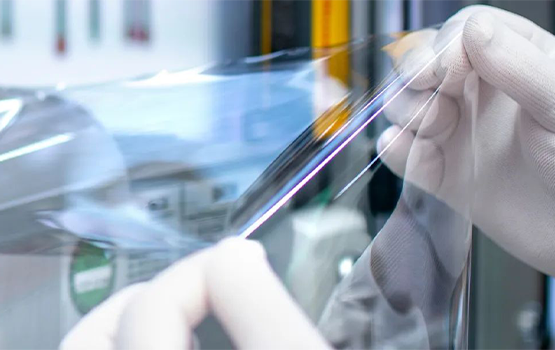

Composite film is a multi-layered material that combines different films, often including aluminum, to create a product with enhanced properties such as moisture, oxygen, and UV resistance. It is widely used in applications like food packaging, pharmaceutical packaging, surface protection, and more. The layers work together to provide better durability and barrier properties than single-layer films.

What are the Benefits of Using Composite Film?

Composite films offer superior strength, flexibility, and protection compared to traditional materials. They are ideal for applications requiring high resistance to external factors such as moisture, heat, and UV rays. Additionally, composite films are durable, lightweight, and easy to handle, making them cost-effective solutions for industries such as food, pharmaceuticals, and electronics.

How is Composite Film Produced?

Composite film is produced through advanced processes such as layering, coating, and lamination. These techniques combine multiple layers of materials to achieve optimal barrier properties and durability. Surface treatments like plasma treatment and laser marking can also be applied to enhance performance and improve adhesion, ensuring the film meets specific application requirements.