Detailed Images

Video

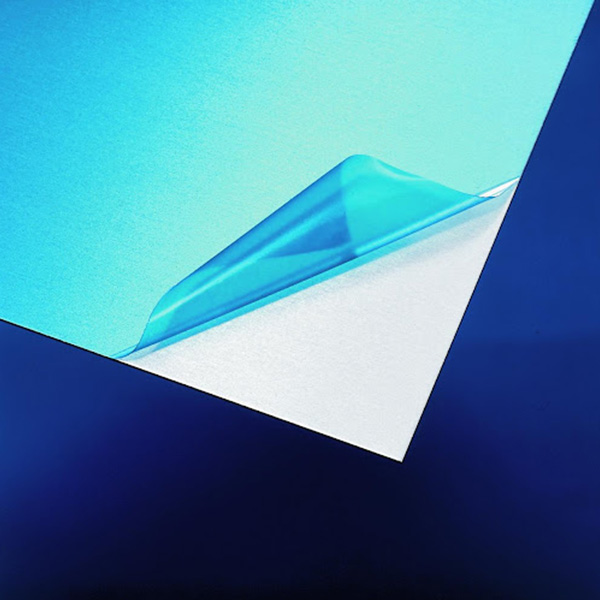

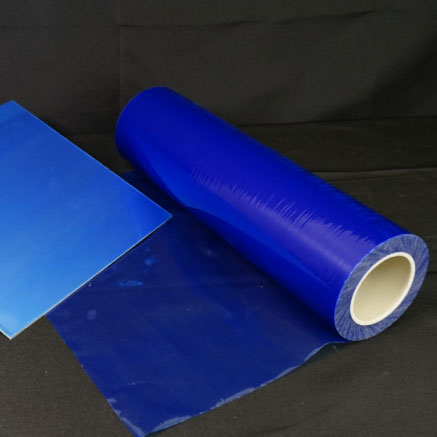

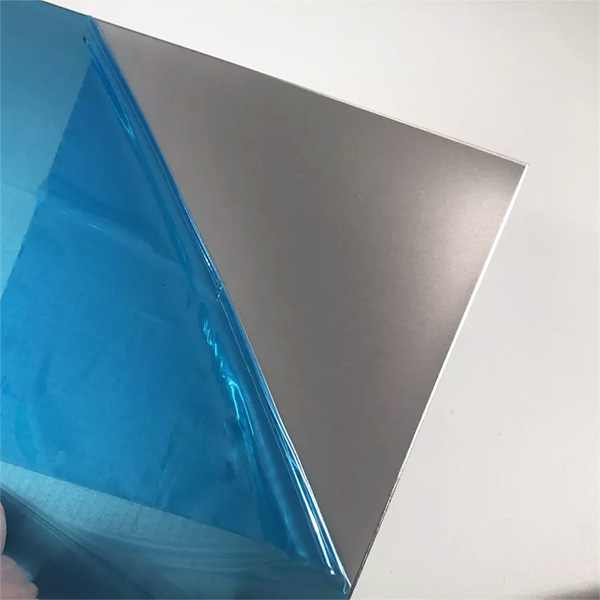

Aluminum Sheet Protective Film For Metal Features:

Superior Protective Properties

The high quality PE film we produce ensures that it effectively resists external impacts, friction and scratches throughout transportation and storage, preventing damage to the surface of the aluminum sheet. Even in complex environments during transportation, PE films provide strong protection, maintaining the surface integrity and appearance of the product.

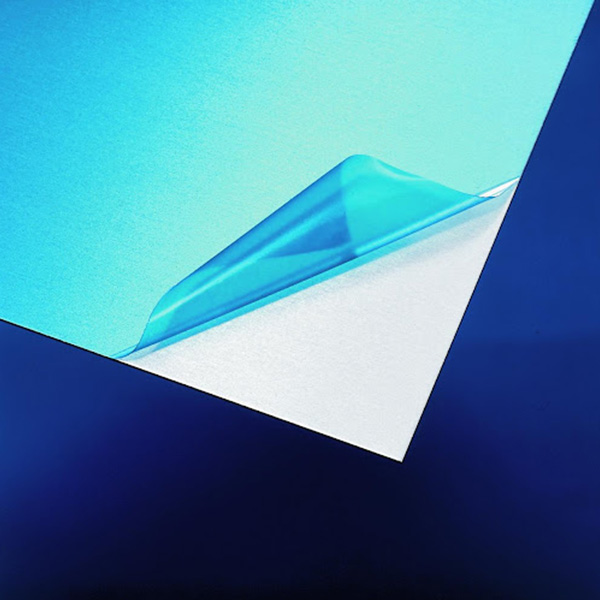

Highly Efficient Removal Performance

A specially formulated adhesive allows for easy removal at the end of use without leaving adhesive residue. Even in extreme environments, such as high temperatures or high humidity variations, the film can be peeled off smoothly, avoiding hard-to-clean adhesive residues and ensuring a clean, streak-free surface.

Versatile Applications

With its excellent flexibility and processability, PE film is suitable for a variety of aluminum surface protection, widely used in construction, home appliances, automotive and many other industries. In different working environments, PE film can provide long-term protection, reduce friction and scratches, and ensure that the quality of aluminum panels is not compromised during production, transportation, and end use.

Aluminum Protective Film Production Process

Blown film process

Firstly, the plastic granules are dried and added into the extruder, which is heated and rotated screw to melt them into continuous molten plastic, extruded through the die, and cooled and blown through the wind ring to form the film with uniform thickness.

Coating process

Next, the adhesive is uniformly applied to the film surface by means of a roller system. Precise adjustment of roller spacing and pressure ensures uniform application of the adhesive, which is finally cured by drying.

Apply to every aluminum surface:

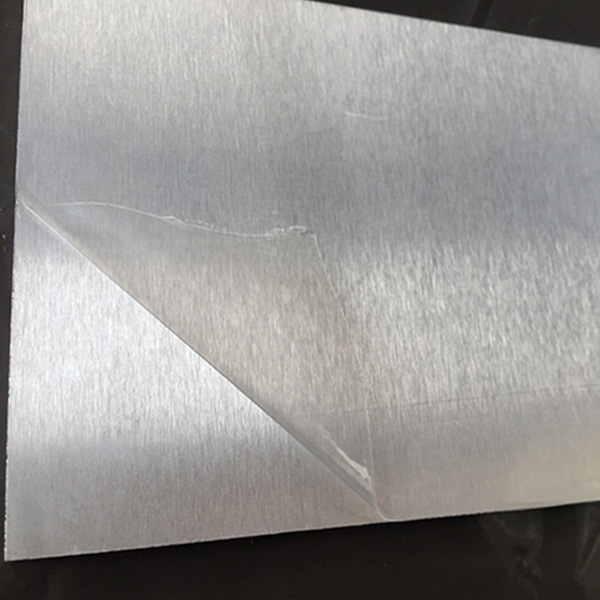

- Finished aluminum surfaces

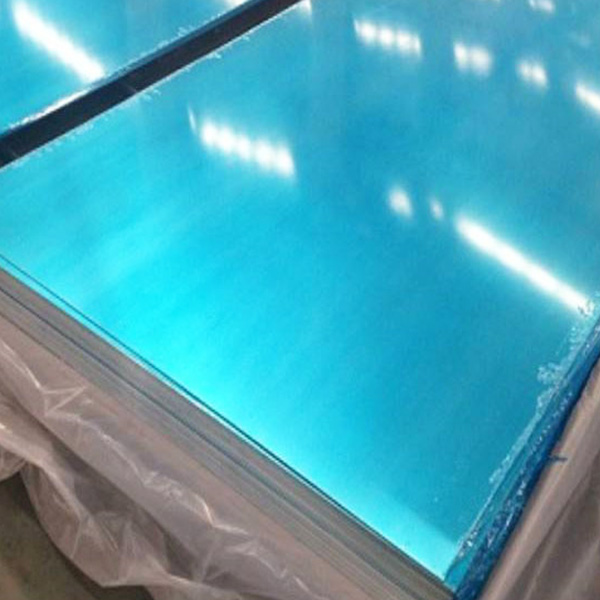

- Bright and mirror surfaces

- Anodized aluminum surfaces

- Matte and textured surfaces

Why Choose Aluminum Protective Film For Metal?

We provide protective films for metal to meet a variety of aluminum sheet processing needs, ensuring that customers can efficiently and conveniently carry out aluminum sheet lamination operations, reducing production losses and improving process efficiency.

Benefits of Choosing Aluminum Protective Film

1. Resist the corrosion of UV rays, acid rain and other natural factors.

2. Prevent corrosion in humid environments.

3. Improve the hardness and abrasion resistance of aluminum plate, anti-fouling and easy to clean.

| Item | aluminum protective film |

| Specification | Customization |

| Material | PE |

| Thickness | 50um-200um |

| Application | All series of aluminum sheet |

Faqs

It will protect the surface of the aluminum plate from scratches, bumps, dust, pollution and other external factors, maintaining the beauty and integrity of the aluminum plate. It also has good weather resistance and corrosion resistance, which can extend the service life of aluminum panels.

Our aluminum protective film is suitable for most aluminum panels, including but not limited to architectural aluminum panels, home appliance aluminum panels, industrial aluminum panels, and so on. It can provide effective protection on different types of aluminum surfaces.

Yes, our aluminum sheet protection film is designed as an easy-to-peel type film. The film can be easily removed after use without leaving any adhesive residue on the surface of the aluminum sheet, ensuring that the aluminum sheet remains intact in the final application.

Our aluminum protective film has good weather resistance and UV resistance, and can resist the erosion of UV rays, acid rain, pollution and other environmental factors. In addition, the film is also corrosion resistant, making it suitable for use in humid and acidic environments.

We offer a wide range of protective films with different thicknesses and adhesion levels, so you can choose the right product according to your specific needs. The adhesion of the film can be adjusted according to the processing requirements of the aluminum sheet to ensure that the film layer can be firmly adhered and will not damage the aluminum sheet when peeled off.

The process of applying aluminum protective film is very simple. Usually, downstream customers can cut the film according to the size of the aluminum plate and then apply the film evenly on the surface of the aluminum plate. It is recommended to operate on a clean and clear surface to ensure the adhesion and effectiveness of the film layer.

Yes, our aluminum sheet protection film is made of PE environmentally friendly material, which is non-toxic, harmless and recyclable. We are committed to minimizing our environmental impact during the manufacturing process and ensuring that our products meet environmental standards.